Regular reviews of overhead allocation methods help companies adapt to changing business conditions and optimize cost control. Absorption costing is the process of allocating all manufacturing costs to products. These include fixed costs, like rent and insurance, and variable costs, like raw materials and labor. The goal is to create a more accurate picture of the actual cost of each product.

Should You Be Trying To Be The Most Expensive In The Market?

- This includes wages for employees or contracted workers involved in making the product.

- Knowing the risks allows you to decide whether or not to use this pricing strategy.

- For example, the cost of setting up a production run for a particular product will likely be directly related to that product.

- For example, if a carpenter makes the chair, the direct labor cost would include their wages and benefits.

Charlie Kaplan talks about assessing product-market fit and shares examples from his work of successful and unsuccessful product adoption. LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must product cost consist of happen to hit your goals. With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made. LogRocket simplifies workflows by allowing Engineering, Product, UX, and Design teams to work from the same data as you, eliminating any confusion about what needs to be done.

Step #5: Calculate the total manufacturing cost

Business owners who do not have a clear understanding of their costs are more likely to underprice their products or services. This can lead to financial problems down the road, as the business may not gross vs net be able to cover its costs and become profitable. The wrong product costing strategy can lead to several problems for manufacturing companies.

- For example, if a product has a high cost and a low selling price, it may be more cost-effective to produce it in large batches to achieve economies of scale.

- With these essential points in mind, businesses can gain valuable insights into their financial performance and optimize product cost accounting.

- Materials, labor, production supplies, and factory overhead are all included in these prices.

- Moreover, when the costs related to production are clearly known, it helps businesses to price their products properly, ensuring the businesses do not incur losses.

- Finally, it’s also possible that they’re deliberately trying to discourage specific customers from doing business with them.

- The relationship between product cost and production cost is closely connected since product cost is directly affected by production cost.

- If production costs varied between $20 and $50 per barrel, then a cash-negative situation would occur for producers with steep production costs.

Product cost calculation examples

- Taxes, royalty payments, and licensing fees also are considered production costs.

- By analyzing the components of product cost, they can pinpoint areas for resource reallocation or process improvement, enhancing productivity.

- By understanding their cost structure, businesses can better identify opportunities for improvement and make informed decisions about how to price products in the marketplace.

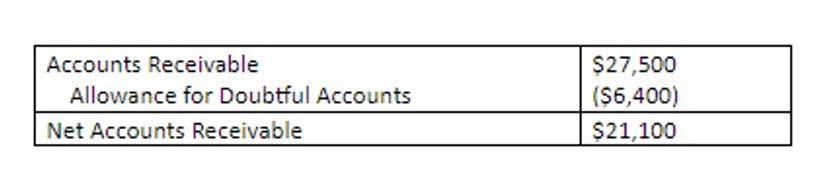

- A balance sheet is one of the financial statements that gives a view of the company’s financial position, while assets are the resources a company owns.

- These unsold units would continue to be treated as asset until they are sold in a following year and their cost transferred from inventory account to cost of goods sold account.

If a company sets its prices too low, it cannot cover its costs and may go out of business. Establishing goals for cost reduction, such as aiming to reduce spending by a particular percentage year over year, can also be beneficial in helping companies stay on track financially. Additionally, taking advantage of economies of scale can help reduce production costs. By considering these key points, businesses can gain valuable insights into their financial performance and make informed decisions about product cost accounting. By understanding their cost structure, businesses can better identify opportunities for improvement and make informed decisions about how to price products in the marketplace. The term “product cost” refers to the expenses incurred during a product’s manufacturing process.

Product Cost and Budgeting

Therefore, understanding the relationship between product and production costs is essential for businesses seeking to optimize their manufacturing operations and increase profitability. With these essential points in mind, businesses can gain valuable insights into their financial performance and optimize product cost accounting. Accurate records are vital for understanding how much it costs to produce a product or service and maximizing profits. By staying on top of their financials, businesses can ensure that their product costs are accurate and allow them to make informed decisions. For an expense to qualify as a production cost it must be directly connected to generating revenue for the company.

Period Costs

The company engaged a consulting firm to help them find out what factors were driving up manufacturing costs. By looking at the historic data on employee timesheets and purchasing costs, the firm was able to understand the areas that were increasing the total https://www.bookstime.com/articles/what-is-product-cost manufacturing costs. Be sure to allocate overhead costs to the respective cost centers (specific departments, processes, or machines in the manufacturing facility that contribute to the manufacturing costs). Indirect manufacturing costs include all other expenses incurred in manufacturing a product except direct expenses. In addition to categorizing costs as manufacturing and nonmanufacturing, they can also be categorized as either product costs or period costs.